Search This Supplers Products:We're running chemical product, mining product(except special approval), feed additive, agriculturalthe exporting of sodidum sulfite anhydrous ,ronggalite lump/powdersodium hydrousufite , sodium fluosilicatesodium metabisulfite , sodium formate, calcium formatezinc sulphate mono/hepta ,zinc oxidesodium carbonate, ferrous sulfate

- Home

- About us

- Products

- Sodium sulfite

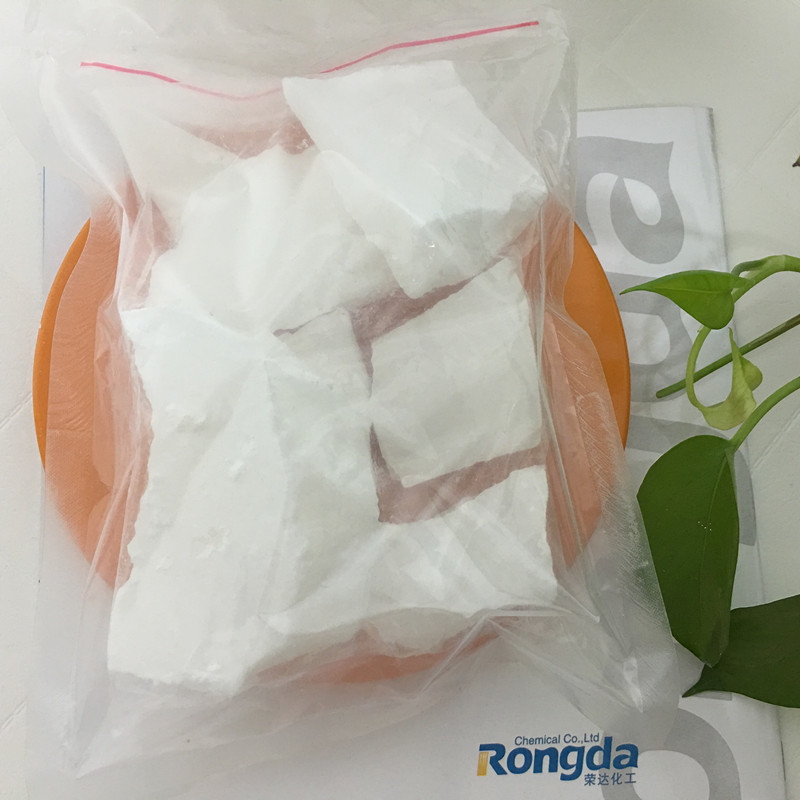

- Rongalite lump/powder

- Sodium hydrosulfite

- Sodium metabisulfite

- Zinc sulphate mono/hepta

- Sodium fluosilicate

- Sodium formate

- Sodium carbonate

- Zinc oxide

- Sodium fluoride

- Copper sulphate

- Sodium hyposulfite

- Sodium sulfide

- Caustic soda flakes/pears

- Fine chemical series

- Lab series

- Calcium formate

- Faqs

- News

- Certificate

- Contact us

The world's first sub molten salt method for cleaning vanadium production line put into operation

publisherJeffrey

time2017/07/04

For more information of the product, please click rongalite lump.

The HeBei steel group and China Academy of Sciences jointly developed by sub moltensalt of cleaner production demonstration project, the world's first sub moltensalt method to clean the vanadium production line in June 12th, put into operation in the HeBei steel group.

According to the Chinese Academy of Sciences project team, the completion and application of the project will completely overcome the existing vanadium technology process, "three wastes" produced a large quantity, the end of disposing difficult, highcost of world problems. After the promotion of the country, the annual source of 500 million cubic meters of waste gas reduction, heavy metal slag 600 thousand tons, 2 million 400 thousand tons of high salt ammonia nitrogen wastewater. It can realize the high efficiency extraction and high valueutilization of the associated chromium resources in vanadium slag, and create anew green development mode of vanadium and titanium industry, which has good economic benefits and anti risk ability.